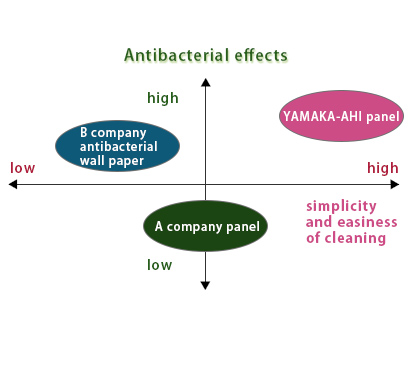

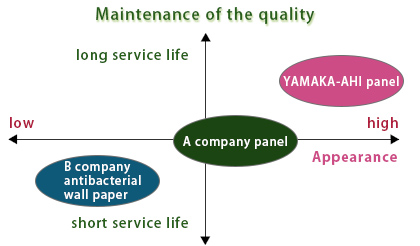

1. Prevents infection within the facility by special coating different from wall paper.

⇒ Strong antibacterial painting on the panel board can prevent propagation of bacteria.

2. Easy cleaning by antiseptic on the robust surface

⇒ Maintains the facility clean and beautiful.

3. This natural material creates a feel of open space which promotes comfort and quality.

⇒ Provides calmness and comfort for the facility users.

Example of an actual construction

Yamaka panel borad is a new type of wall panel made out of natural materials with a firm surface and antibacterial technology, which features a distinguished look and quality different from ordinary wall paper and polyester-resin treated plywood. This product effectively kills 95% of all bacteria and prevents infection within the facility. Easy to construct.

1. LGS65×40 303 mm pitch

2. An 12 mm area of LGS needs to be fasten together with screws

3. Glue the AHI panel together

Side view of the testing material LGS + 12 mm

Fasten the control panel with screws in 150 mm pitch.

4.Completed construction

(the completed view of a test installation)

Result ( still in progress )

Before repair

After repair

repair instructions

1. Repair flaws and dents with “ALTECO GEL”".

2. Scrape the surface of the panel to make it flat and smooth.

3. Wipe off excessive “ALTECO GEL” from around a flaw or dent by a waste cloth.

4. Spray “ALTECO SPRAY PRIMER” on the part repaired with “ALTECO GEL” but let it harden completely before spraying. (It will harden instantly.)

5. Sand repaired parts to make it flat and smooth. (around #320→#600 grit sandpaper)

6. Match the finish of the repaired part to the other parts around it using an AF-AIR FLAT (12-938).

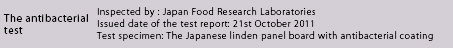

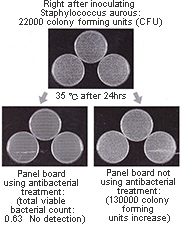

Testing method : JIS Z 2801: 2010 "The panel board with antibacterial treatment-Testing method for antibacterial activity, antibacterial effects"

| Testing bacteria: Staphylococcus aurous | Blank (The panel board with non antibacterial treatment) | The panel board with antibacterial activity against Japanese linden. |

|---|---|---|

| Staphylococcus aurous | 1.3×105 | < 0.63 Non detection |

| Escherichia coli | 1.0×106 | < 0.63 Non detection |

The total viable bacterial count of the panel board with antibacterial treatment demonstrate a decrease in comparison of antibacterial treatment panel with non treatment, less than 1/130000 at Staphylococcusus aurous, and less than 1/1000000 at Escherichia coli.

| Test items | The standard of the decorated panel board FW type with special treatment | Test result |

|---|---|---|

| Category- 2 impregnation test | Qualification : The length of each sides of unpeeled adhesive layers of test pieces must be over 50mm. | No peelings on the adhesive layers |

| B test for repetition of cold and heat | Qualification : The surface of testing pieces must not have any cracks or blisters, peelings, discolorations and lusterless remarkably. | No cracks or blisters, peelings, discolorations and lusterless on the surface. |

| B test for water‐resistant | The surface of testing pieces must not have any cracks or blisters, peelings, discolorations and lusterless remarkably. | No cracks or blisters, peelings, discolorations and lusterless on the surface. |

| B test for contamination | Must not have remain colors on the surface of testing pieces. | No color remaining |

| B test for abrasion | Must be over 50 at the abrasion level and 0.1 at the abrasion loss. | the abrasion level: 59 / the abrasion loss: 0.052g |

| Tensile test of surface | Tensile test of surface (Must be over 0.4[N/mm²] at the average adhesive strength of the collected specimen. | 1.4[N/mm²] 1.4[N/mm²] 1.5[N/mm²] 1.5[N/mm²] |